Welcome to Kepro

Proven Everywhere

- 4 Distribution Centres

- 100+ Dealers

- 10+ In-house Engineers & Designers

- 100+ Products

We provide variety of material handling and welding solutions across industries such as Oil & Gas, Construction, Railways, Iron & Steel, Power, Chemical, Food Processing and Ship Building. We pride ourselves on retaining all our customers by providing highest quality products and after sales support.

Our Products

Welding Equipment

What We do

International Standards of Quality Testing

We have full range of in-house testing facilities. We check our products thoroughly to meet stringent standards. We also provide third party testing

on request.

Visit our Lab website at

www.keprolabs.com

Why Choose Us?

Our Presence

Cement Industry

Construction Industry

Oil Industry

Power Sector Industry

Railway Industry

Steel Industry

And Many More..

Our Facilities

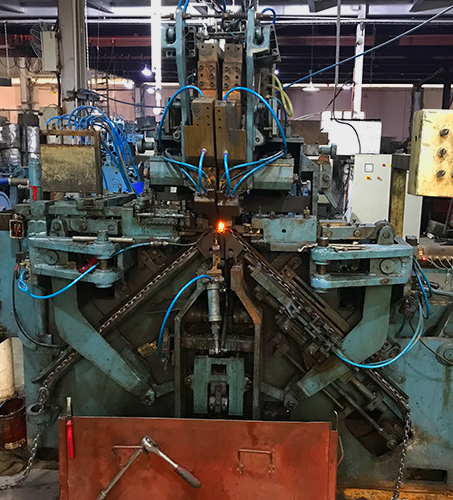

Chain Welding Machine

Hydraulic Power Press

Jib Crane

Lathe machine

Milling Machine

Winch Testing

And Many More..